Project Description

We, YT Marine, have a client from Malaysia Shipyard. They bought the foam fender for a few batches.

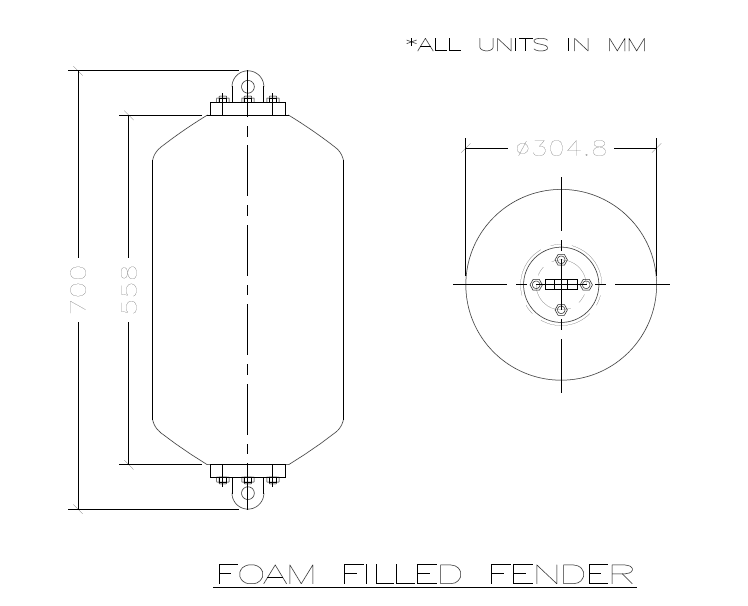

Commonly they will buy from us the 300mx700 small size type. This is the drawing.

Product Description

These are the product pictures we produced for him below.

The foam jetty boat fender inner side material is EVA foam, density is around 100kgs/cbm. So then one fender weight is around 16kgs.

The outer side is SPUA coating, which is anti-sea water, and anti-sun shine.

The color is black of this client’s order product, we can make whatever color you want. And our special outer material SPUA can ensure the color is the same for fifty years.

It is black, we use the film to cover it.

The drawing is a cone shape, and we made a flat shape at the ends. The flat end has a bigger contact area, which is good for bumping.

Broken Foam Filled Fender

You can find the fender is broken in the flange area.

Analysis Reason for Fender Broken

From the pictures, we can see the reasons for the broken:

- The flange cut the fender body, causing the broken.

- The fender diameter is too small, and the bumping weight is too big.

How to resolve the Broken problem?

- Our fender design compression is 50%, we can enlarge the fender size to suit the heavy bumping. Then the flange will not cut the foam-filled fender body.

- We can change the end flat shape to a cone shape. It is the cone types below.

Compression Test

Actually, our foam Quay fender quality is very good, we can do the compression as in the below test picture. It can recover as the original.